Our sculpture casting uses a blend of traditional methods and advanced modern techniques

Our sculpture casting uses a blend of traditional methods and advanced modern techniques

Milwyn can bring any idea from paper to patination with professional expertise. We also ensure that you are given the knowledge to keep your bronze looking its best, after our heartfelt production.

Project Management & Design

As experts in sculpture casting, we ensure that all areas of the creation of a sculpture are managed to help artists achieve their desired outcome. From help with design and presentation, 3D modelling, structural work, and engineering, to delivery and installation, our years of experience and a list of trusted sub-contractors, can help at any stage of sculpture casting to see through the artist’s vision.

Origination, pattern making & Enlargement

Taking advantage of modern computer-assisted carving as well as traditional sculpting methods, we have the ability to realise any project in any scale the artist may want, despite limitations in information available. We can offer assistance with the sculpture casting of a restoration project or a sculpture that requires repairs.

Silicon Moulding

We only use the best quality silicon rubber and fiberglass, producing durable and multi-use rubber moulds designed on practically any object or material. This moulding process is able to pick up the finest details and ensures the best possible results for your sculpture casting.

Lost Wax Casting

The majority of our castings are made by the lost wax technique, using high-quality ceramic shells. For some basic shapes such as bases and plates, we will sand cast.

Chasing & Fabrication

Taking advantage of our staff’s vast experience in blacksmithing, we pride ourselves on our chasing and fabrication skills in bronze and steel. Our highly skilled sculpture casting team are able to ensure there are no visible traces of joins on the artists sculpture.

Patination

This is the final stage of bronze sculpture casting, and at Milwyn art foundry, we pride ourselves on our patination and finishing. We encourage the involvement of the artist at this stage but offer expert advice throughout the patination process, showcasing how different finishes react to different lights. On top of this, we offer an in-house gilding and painting service.

Maintenance

Milwyn art foundry can provide maintenance on damaged historic sculptures as well as help artists take care of their bronze.

Once the final piece is complete, we give all of our artists a booklet highlighting the steps to keep their work of art looking its best. For more information on this, including an excerpt from our ‘Caring for your Bronze’ booklet, then visit the Resources page.

Architectural work

Vacuum casting

A new addition to Milwyn for small and detailed castings. Using jewellery casting techniques on a slightly larger scale.

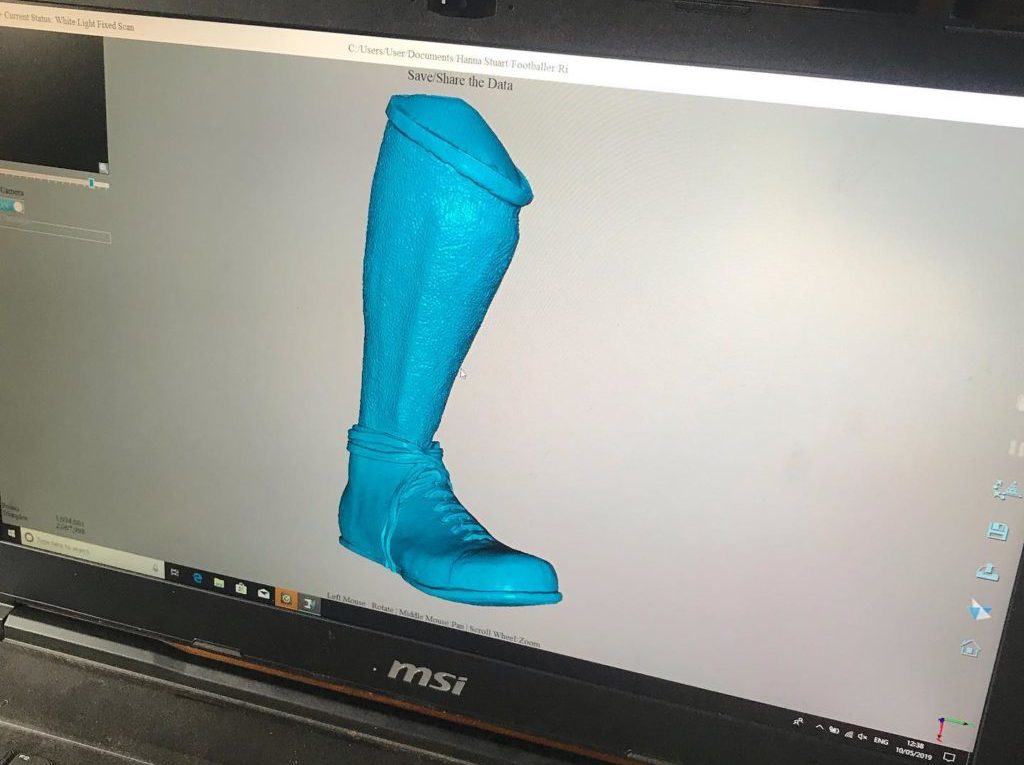

Milwyn 3D

Milwyn 3D has been set up to compliment and develop the work done by Milwyn Casting, using state of the art 3D printing technics to transform ideas and designs into solid objects, ready for moulding or direct casting. Our in house services include 3D scanning, digital manipulation, preparation for 3D printing and 3D printing for direct casting.